Chain conveyors 4 pcs

We have successfully completed and produced 4 pieces of CHAIN CONVEYORS for a factory processing metal materials. The purpose of transporting iron particles in the production phase. The transporter is constructed very robustly and ensures uninterrupted work in the most difficult production conditions.

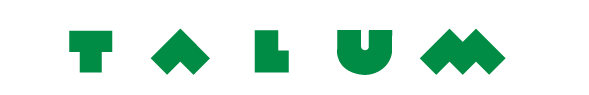

Belt transport conveyor.

A belt conveyor was made for a factory that processing metal materials.

Dosing in trucks with loading bellows

Presentation of the installation of a loading bellows from a silo into a truck or tank. The loading bag is ATEX designed to ensure safety. The client has gained safer management, as it is no longer necessary to climb on top of the tank or truck. Dosing and lifting the bellows works according to the level of granulation on the truck, automatically.

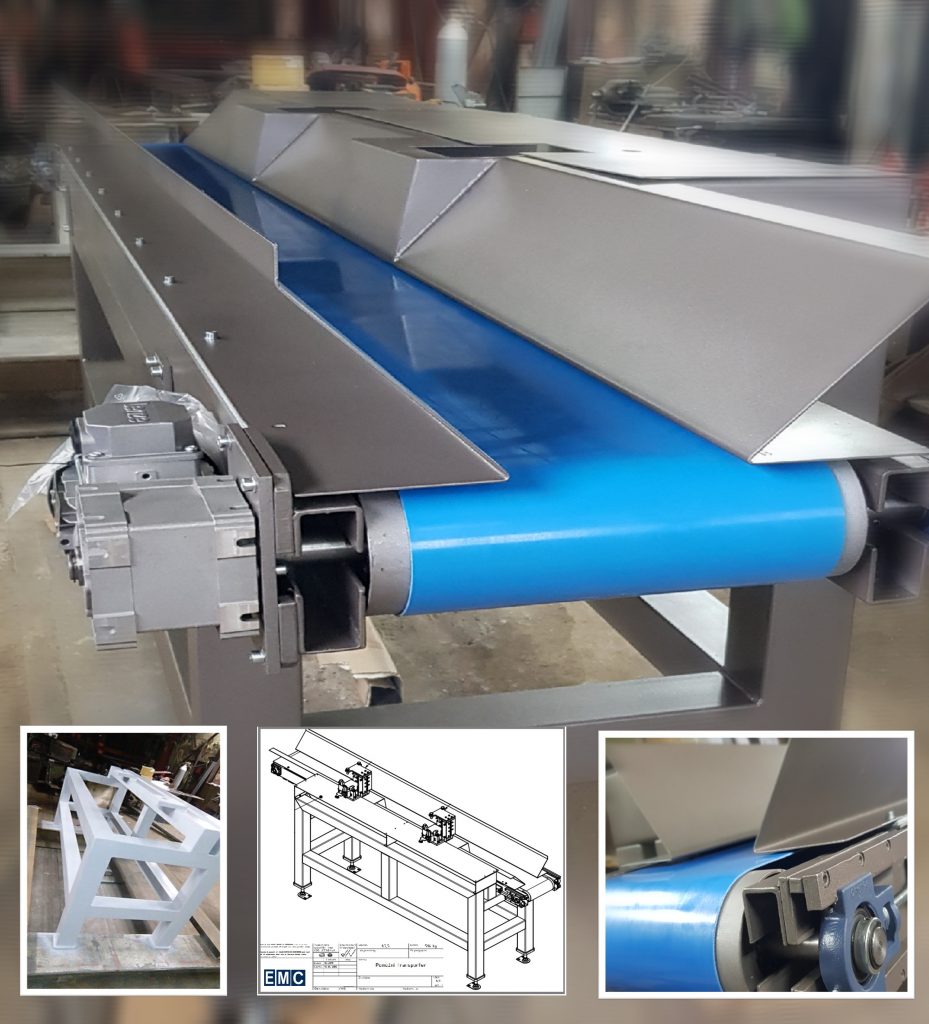

Dosing from silo to production line

For the purpose of producing plastic equipment, we created a new dosing system from a silo with a dispenser and screw conveyor transportation system.

BIGBAG machine for empty bags

For the needs of the market, we have produced with Wamgroup a sophisticated machine for emptying BigBag bags. Attaching the BigBag bag to the frame with a forklift and just open the outlet of the bag. The pneumatic arm system ensures the smooth emptying of BigBag bags.

Service of ATEX electromotors.

In the “Refrigerating furnaces in metallurgy” project, we serviced a large number of ATEX special electric motors for the client. Replacement of all machine parts (seals, bearings…) and winding of the stator.

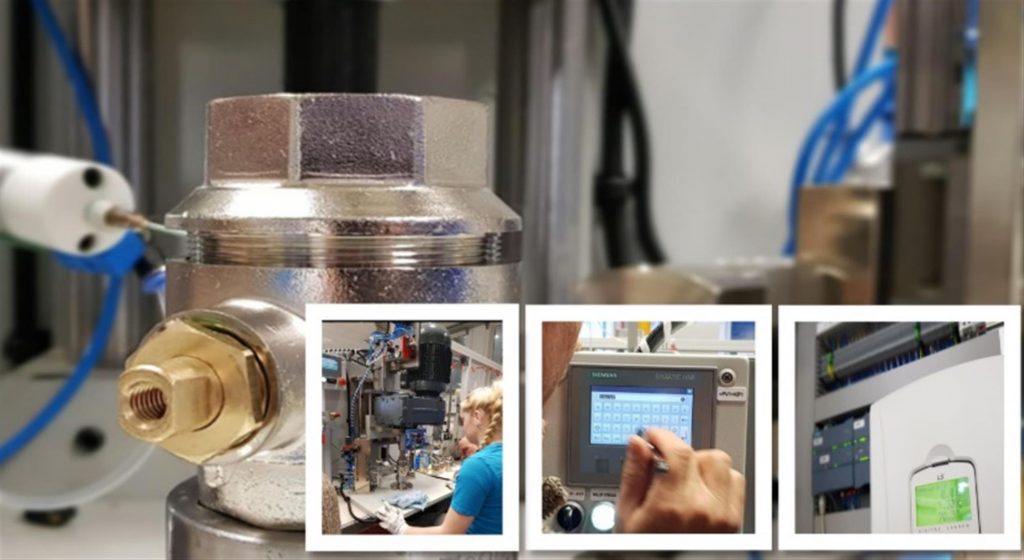

New valve making machine

For the mass production of kitchen fittings, we made an automatic assembly machine; screwing and tightening with precise force. With the machine, we combined three production processes and accelerated the production cycle.

Automation of an old packaging machine

For the metallurgical company, we implemented a fully automated solution, rebuilding the control of the “Signode” packaging machine with automatic operation. We used a Siemens S7-1200 controller and installed a larger number of sensors on the machine. They had the old device controlled only by time relays, which were not coordinated with the old machine assemblies, but now they got a new “smart” for automatically winding iron strips onto reels.

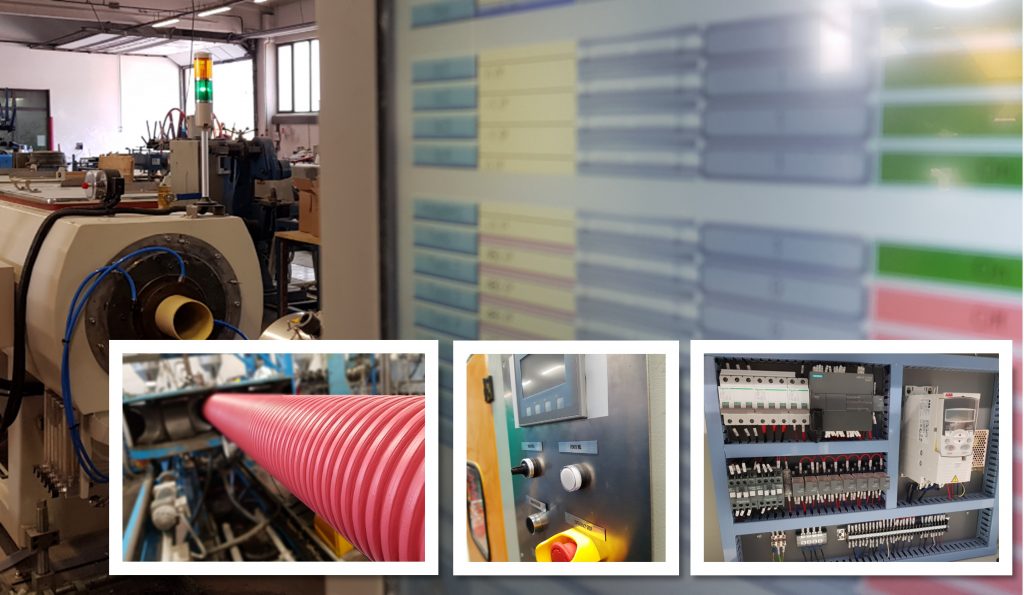

New industry SAW control

A manufacturer of plastic products needed new control of the entire machine – a plastic cutting saw. We implemented a completely autonomous mode of operation according to the wishes of the customer. Equipment: SIEMENS SIMATIC S7-1200 and OP “operating panel for management”.

Control of DC 2MW drives

We have implemented a control system for large electric DC motors (6x 2MW DC), for the lubrication and control system. We used a Siemens S7-1500 controller with a touch panel management and control panel.

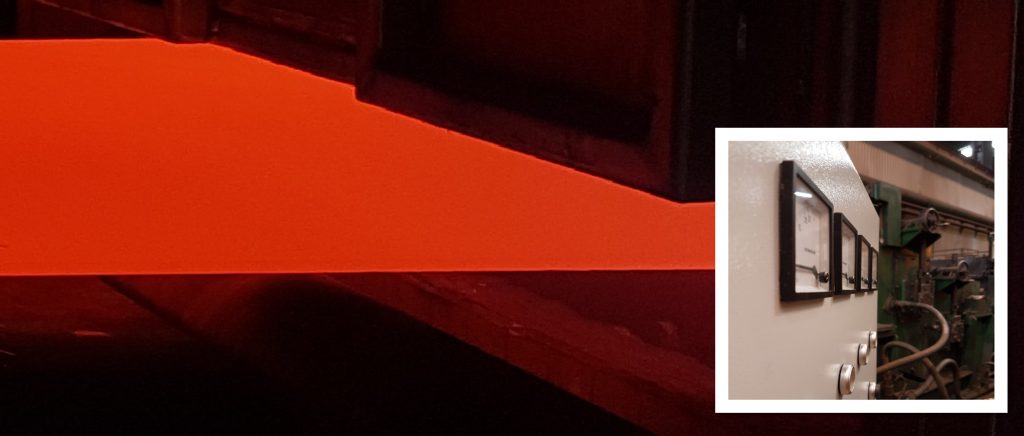

Control of sheet metal furnaces

Implementation of “Monitoring and control of the ignition of a 100m long continuous furnace” on a line for non-directional electroplates. A solution with 12 switch blocks (electric box) and controlled gas ignition in the furnace with a high-voltage “HV” transformer.

Control of the sheet metal brush machine

Automation & restoration of an old brush machine. For a metallurgical company, we made an update of a steel brush machine for sheet metal. They gained better control over the operation of the brushes and a higher quality of the final product.

New label cutting machine

For the production process, we have developed a machine that automatically cuts out labels for the purpose of marking the final products.

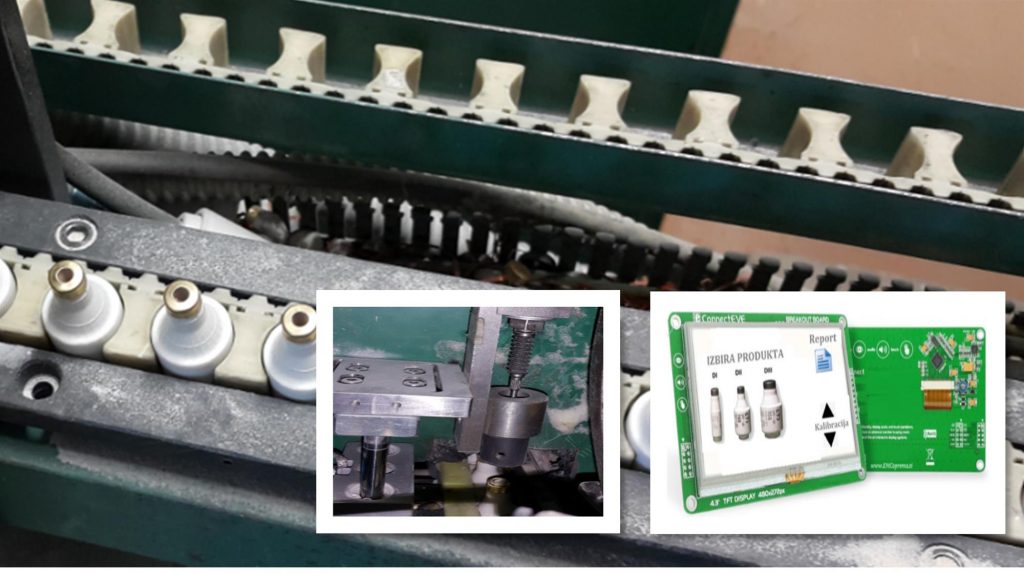

Quality automatic control of fuses

The customer wanted to eliminate errors and complaints from their customers, so we designed and implemented a quality monitoring system and error detection (sand level, correct placement of the cap…) of their “fuse” products. We developed our own electronic system-control panel with “touch” LED display, FESTO pneumatic equipment and KEYENCE sensors.

Automation of the sheet metal press

The industrial press for steel coils was fully automated and autonomous operation was carried out without the intervention of the worker. The purpose of device update is life protection and automatic operation. We used Siemens S7-1200 CPU and Sick sensors.

PLC Control of 28 vibrating lines

Implementation of control and management of 28 pcs of vibro tables in the production of concrete weights for industrial machines. Using Omron controllers.

Safety restoration of 14 grinding machines

For a factory of glass products, we created a safety service solution with a machine and a pneumatic regulation system for safe movement of the door.

Transport line for bottles

Together with the Italian manufacturer ALLGLASS S.r.l. we made a project of a transport line in the production of glass products, where we set up the entire line of transport, manipulation and implementation of inspection machines for products – 800 degrees bottles.

International trade fair “MOS”

We presented our products and services at the “international craft fair” in Celje.