CATALOG

Catalog of equipment from WAMGROUP. All bulk handling equipment and silo equipment are presented.

Electric Motor Vibrators

MVE electric motor vibrators or. vibrator motors are the most commonly used motor vibrators that can be used to manage the flow of materials on hoppers or silos to improve material drainage. Vibratory motors are also used on vibrating machine for various purposes. Options: AC, DC, ATEX ExII2GD, IECEx certification, miniature version.

Pneumatic vibrators

Pneumatic Turbine Vibrators

The pneumatic rotary turbine vibrator works with a turbine and is equipped with eccentric balls. The higher the air velocity, the greater the force we get.

Pneumatic hammers – PISTON

Vibrations with vibrating pneumatic vibrators are generated by the movement of the inner floating piston. It acts as a hammer at slower intervals.

Hidraulic vibrators

Hydraulic vibrators are suitable for easier emptying of materials in trucks.

– Strong vibrations with large amplitudes

– Adjustable by oil flow

– No maintenance

– Long service life

– Ideal for connection to on-board hydraulic systems

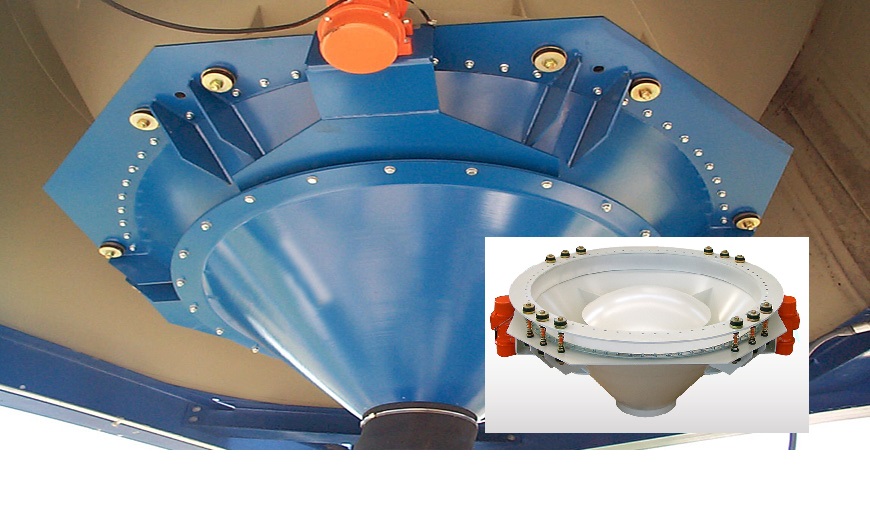

Bin activators for silos

The BA Bin Activator is a device of tapered conical shape that, due to vibration, facilitates material flow from hoppers or silos. It consists of a seamless carbon or stainless steel cone manufactured on a sheet metal lathe, a seamless SINT engineering polymer seal with integrated upper and lower flange, suspensions for connection with the silo cone, as well as one or two electric OLI motovibrators.

Micro Dosing Machines

Solution for accurate dosing of small quantities.

Possibility of two dosing types, Volumetric or gravimetric dosing.

– DCC – Dosing with measuring scales “scales”

– DVC – Continuous dosing with screw screw

– Accuracy: between 0.5% and 1.0%

– Quantity: 1.47 dm3 / h ~ 244dm3 / h or max. 0.24 m3 / h

– Weighing cells: 45kg, 60kg and 120kg

– Dosing hopper: 12 dm3 or 20 dm3

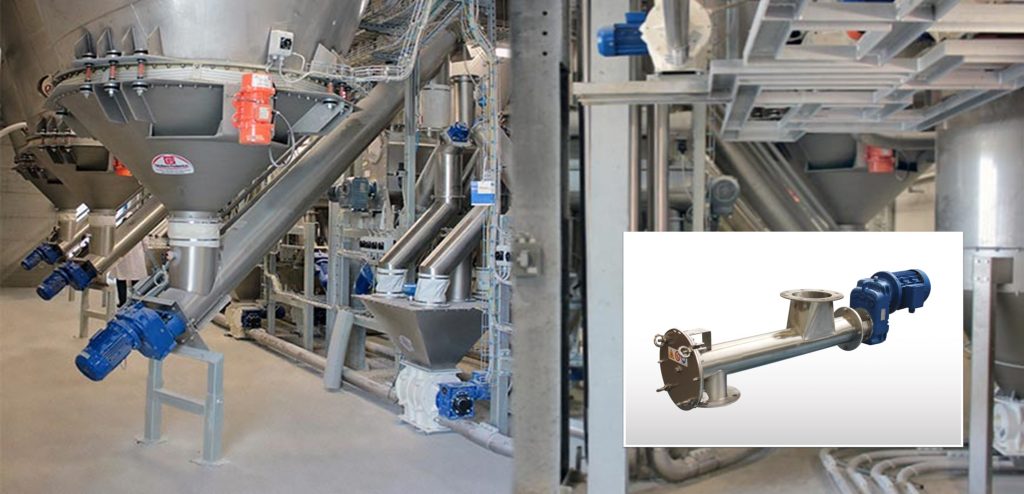

Screw conveyors

Screw conveyors – tubular

The system of screw conveyors is very versatile, offering various standard solutions for handling powdered or granular materials.

Screw conveyors – open

Modular CA screw conveyors are offering many solutions for transporting powdered or granular materials. CA conveyors are made of carbon steel with appropriate surface treatment.

Food conveyors

TXF screw conveyors are specially designed for the needs of the food industry. This screw conveyor is made of stainless steel and offers high quality surface treatments. The production of manufactured components ensures a perfectly smooth surface, so the rest of the material is reduced to a minimum.

TXF conveyors are available with ATEX, Zone 22 or Zone 21, European Regulation (EC) 1935/2004-compliant, Standard 304L or 316L stainless steel certificates on request.

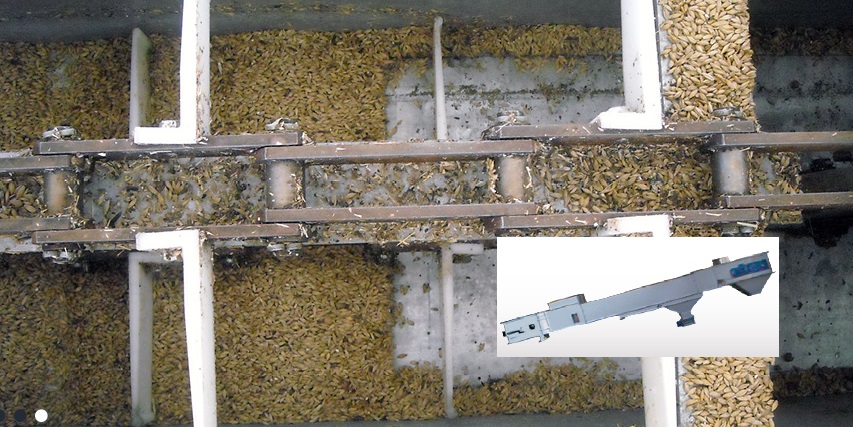

Chain conveyors

Chain conveyors are designed to carry dry solids. TCG chain conveyors specialize in the transport of grain, flour or similar materials. The hot-dip galvanized housing with flanges is modular. The conveyor is not ATEX certified, only drives and electrical assemblies.

– For cereals, flour …

– Flow up to 1000 m3 / h

– Length up to 100 m

– Over chains with compressed or forged links

– Chain guide improved with manganese steel

– Rotary sensors

Chain conveyors – HD

Production of heavier chain conveyors. Purpose of transporting iron or hard particles in the production phase. The conveyor is constructed very robustly and ensures smooth operation in the toughest production conditions. Custom design.

– For heavier, abrasive materials

– Over chains with compressed or forged links

– Rotary sensors

– Design & manufacture in Slovenia

Belt conveyors

Manufacture of belt conveyors. Purpose of transporting bulk cargo in the production phase. The conveyor is constructed very robustly and ensures smooth operation in the toughest production conditions. Custom design.

– Design & manufacture in Slovenia

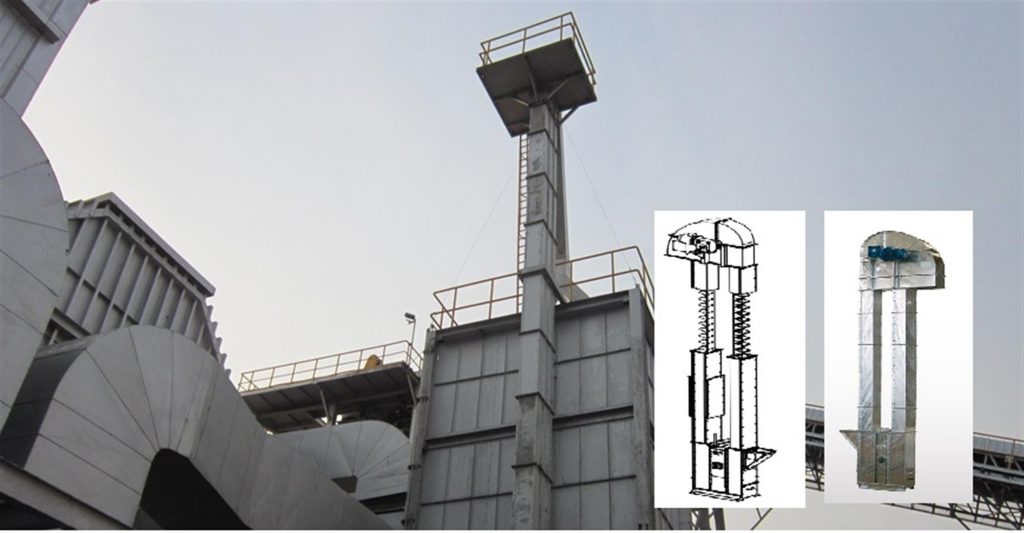

Elevators

ELEVATORS are used for vertical lifting of small aggregates such as carbonate, lime, limestone, sand, minerals and similar materials dry, powdery, abrasive, ATEX II 3D T4 design… Height EC, EF, EI up to 44 meters and EHN height 60m. Special versions for temperatures up to 200 ° C.

Type elevators for:

EC – For cereals / flow up to 1,200 m3 / h

EF – For flour / flow up to 1,200 m3 / h

EI – For fine aggregates up to 5mm / flow up to 500 m3h

EHN – For units up to 50mm / flow up to 310 m3 / h

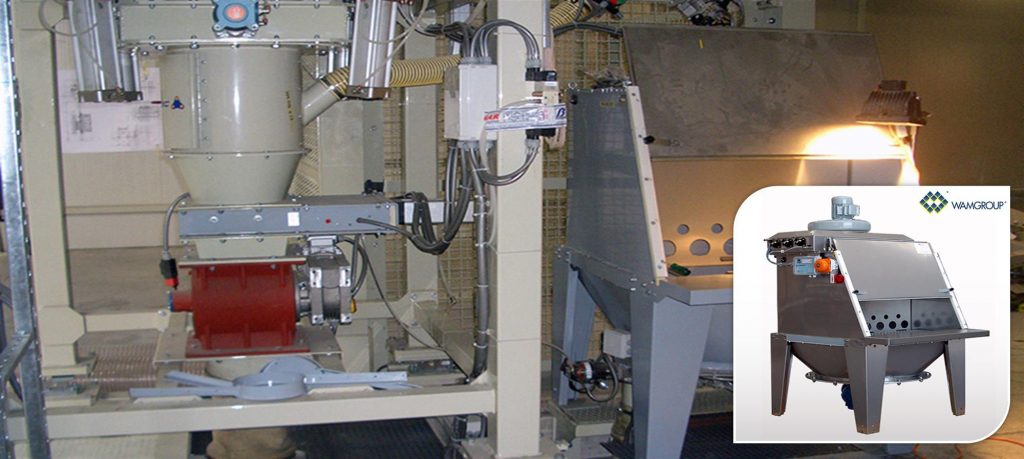

Bigbag dosing & discharging

BigBag emptying machine

A modular system for separation or emptying BigBag bags. Easy to insert (FIBC) BigBag bags into the carrying frame. The system allows dust-free emptying.

BigBag filling machine

BigBag filling stations enable efficient filling of bulk materials into BigBag bags.

Bellows

Filling Bellows are used for efficient, dust-controlled loading of dry, dusty or solid substances into tanks or open trucks. The bellows have built-in inner pointed cones that ensure a smooth flow of material and outer double bellows due to dedusting.

Manual emptying of bags

Manual bag emptying machine

The operator places the bag on the machine and pushes it onto the machine. He then manually cuts the bag with a vertical cut and shakes the contents. The contents of the bag are drained through a funnel or a special rotary emptying device for further process or. storage in a silo. The machine has a built-in fan that cleans dust during emptying.

Valve for silo

SLIDE valves Sliding valves are used when we have a flow of powder or granulates with the help of gravity. They are also suitable for larger material granulations.

FLAP “Butterfly” Valve Flap valves for closing silos, and bunkers containing powdery or granular materials are more affordable than slide valves and are used for fine granulation of materials.

The DUAL “DVA” valve is a gate valve with one inlet and two openings for diverting the flow of powder or granular materials. The materials used allow quick cleaning and maintenance, in addition to offering great wear resistance.

Rotary valve

Rotary dosing valves

Rotary Valves for material dosing are the ideal solution for controlled emptying and dosing of powdery or granular materials from silos, pneumatic transport systems, or cyclones.

Pneumatic valve

Pneumatic valves

Type VM / VMM are used to intercept the flow of material in pneumatic transport systems or other pipelines. In addition, they can also be installed as a device for closing silo filling pipes. – Diameter: 13 mm to 200 mm (for VM) – Diameter: 40 – 50 – 65 – 80 – 100 – 125 – 150 – 200 mm (for VMM) – Temperature, working: -20 ~ 80 °C

Relief valves

The pressure relief valve has one decisive advantage in that, due to the moment of inertia of the coil springs in the VCP pressure relief valve, the pressure ratio is restored quickly, but not immediately. VHS-C, on the other hand, does the job in real time. A perfect pressure balance is achieved. – Connection to the central suction system “VHS” – They prevent clogging – Patented by Wamgroup

Level switch

Measuring levels

A switch with the function of detecting the minimum or maximum level of material inside the hoppers. Operation with a rotation system or vibrating fork.

– Rotary level switch (For bulk material, biomass…)

– Vibration level switch (For finer, liquid materials)

KIEPE switches

Emergency stop safety switches Kiepe GmbH

Emergency stop switches for transport systems. Housings made of aluminum or cast iron, optionally in ATEX. Range of equipment:

– Pull switches on steel rope;

– Switches for lateral tape shift;

– Wheel limit switches

– Mounting equipment (red rope, springs…)

Pipe elbows

Radial Pipe elbows

Which are inserted as a connection in pneumatic transport pipes. Their special geometry enables redirection of the material flow with minimal wear and minimal maintenance. Prevents material jamming and smooth flow.

Pipe elbows

Pipe elbows

Are used to change the direction of flow in piping systems. Installation becomes faster and durability increases dramatically. Their great flexibility and excellent wear resistance result in double durability, as the elbows can simply be mounted in the reverse position as soon as any signs of wear appear. Reduced noise level.

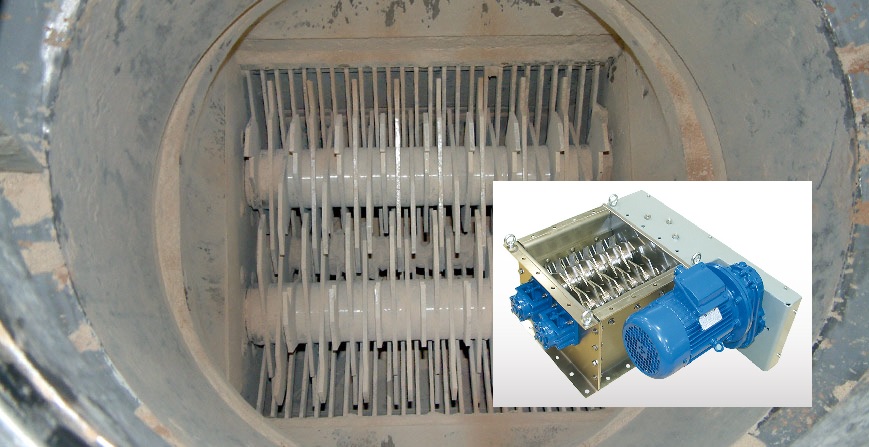

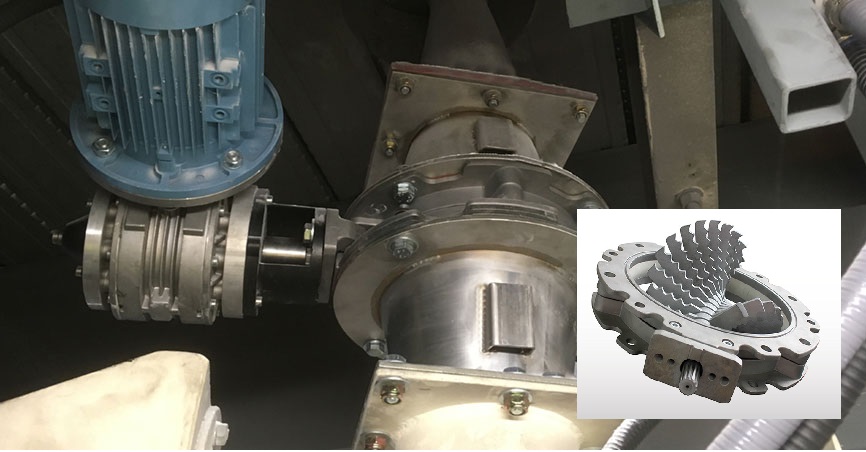

Lump Breaking Feeder Valves

Crushing valve for crushing or grinding of aggregates of solids, which, after crushing, are discharged through an opening for further processing. A solution for breaking down materials. It is particularly suitable for hygroscopic materials and those compressed under pressure, such as sugar, salt, silicates, chemicals, and food products in general. The valve can be installed in the filling and/or discharge pipes, for emptying or filling Silos, containers, or screw conveyors.

– Cylindrical connection

– Interchangeable blades

– Improved material flow

– Option for the food industry

Lump brakers

The DLP Lump Breaker is an efficient, economic machine specially designed for breaking up friable lumps in bulk materials discharged from silos, bins or hoppers.